WHY DGS

18 Years of Dominance: DGS Innovation

The global benchmark in HDPE military vessels—built for battle-ready safety, durability, and performance.

Why DGS Boats?

At DGS Boats, we are redefining naval engineering with cutting-edge HDPE technology, delivering vessels that excel in durability, safety, and performance for the most demanding missions. Our commitment to innovation and excellence has made us a trusted partner for military, law enforcement, and search and rescue teams worldwide.

Our History: Forged in Innovation and Excellence Since 2007

Since 2007, DGS Boats has been at the forefront of naval innovation, pioneering the use of HDPE (High-Density Polyethylene) to create military-grade vessels. Our journey began with a vision to build boats that could withstand the toughest conditions, and over the past 18 years, we have earned global trust as the leader in HDPE boat manufacturing.

We have partnered with the Brazilian Navy—the second-largest naval force in the Americas—to deploy over 150 DGS vessels in diverse missions, including:

- Coastal patrols

- Fast boats operating from attack frigates

- Drug trafficking combat operations in the Amazon rainforest

- Oceanographic research at the Brazilian Navy’s Antarctic base

- Patrolling Brazil’s 22,500 km of navigable rivers to secure vital waterways

Our vessels also support a wide range of clients, such as the Brazilian Fire Department, Federal Police, Brazilian Army, National Environmental Agency, private oceanographic and river data survey companies, and numerous governmental agencies, delivering reliable, high-performance solutions.

Our Team: Passionate Experts Behind Every Vessel

Our greatest asset is our team—over 50 passionate sea enthusiasts and highly skilled professionals, including designers, engineers, project managers, builders, craftsmen, and trainers. Working as a cohesive unit, they bring extensive field experience to ensure every vessel meets the rigorous demands of military, law enforcement, and SAR operations. Their dedication to precision and excellence is the driving force behind our success.

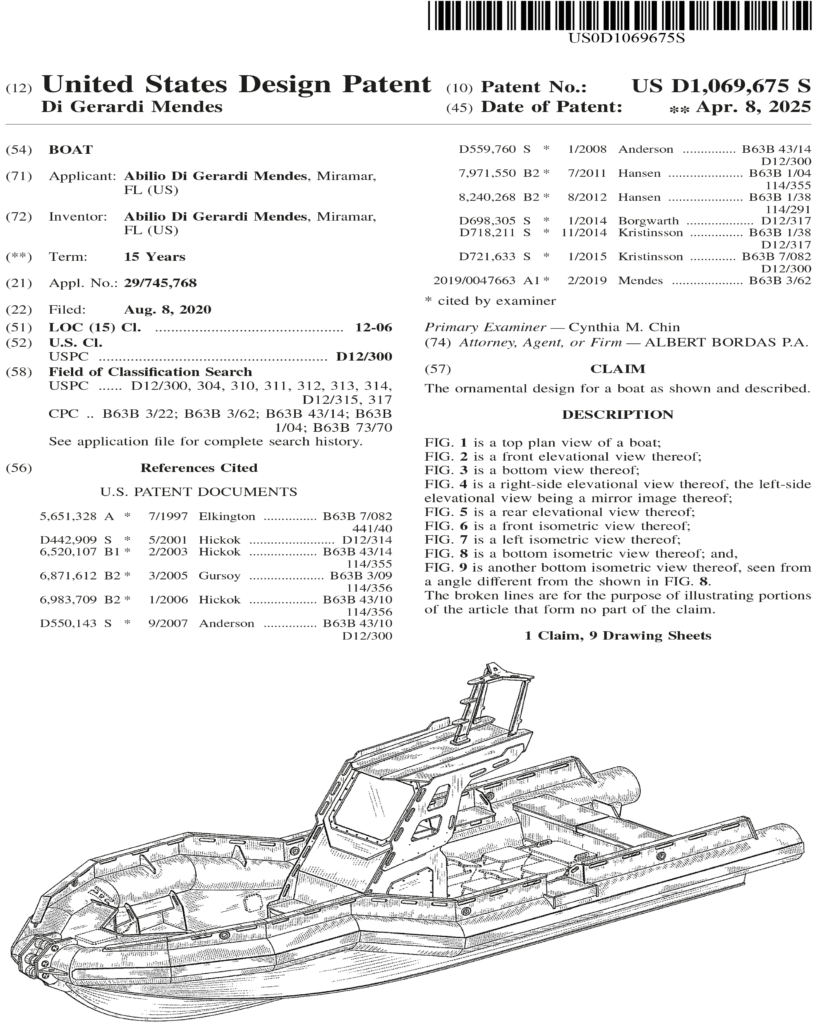

Why HDPE? The Technology That Sets Us Apart

HDPE (High-Density Polyethylene) is a high-strength thermoplastic that offers unparalleled advantages for naval applications:

- Impact Resistance: Outperforms fiberglass and aluminum in shock absorption, making it perfect for tactical operations and rugged terrains.

- Extreme Durability: Rust-proof, crack-proof, and corrosion-resistant, thriving in harsh marine environments for decades.

- Low Maintenance: Requires no frequent painting or repairs, significantly reducing operational costs.

- Thermal & Acoustic Stability: Minimizes heat and sound transfer, ensuring crew comfort and stealth for covert missions.

- Natural Buoyancy: With a density lower than water, HDPE boosts stability and safety, unlike aluminum and fiberglass, which naturally sink.

- Fire Resistance: Self-extinguishing and resistant to sustained combustion, enhancing safety in emergencies.

- Eco-Friendly: Recyclable with a low carbon footprint, making it a sustainable choice.

| Feature | DGS Boats (HDPE) | Marine Aluminum Boats | Fiberglass Boats |

|---|---|---|---|

| Durability/Life Span | ✅ Ultra High – Last decades in harsh marine environments, built for extreme conditions / 40+ Years. | ❄️ Medium – 10–20 years depending on upkeep. | 🔧 Medium – 10–15 years with regular maintenance, gel coat fades, susceptible to osmosis, cracks over time. |

| TCW – Total Cost of Ownership | 🔐 Lowest – Minimal maintenance and long service life. | ❄️ Medium – Frequent inspections, dent repairs, frequent galvanic anode replacements to combat corrosion. | 💸 High – More expensive upfront and over time due to maintenance and repairs. |

| Corrosion Protection | ✅ ZERO corrosion, No galvanic anodes needed, it’s a high-performance thermoplastic. | ⚙️ Aluminum boats require galvanic anodes constantly to combat corrosion, especially in saltwater. | 🌊 Susceptible to osmosis and UV degradation. |

| Impact Resistance | ✅ Very High – Absorbs shocks much better than fiberglass and aluminum—ideal for tactical ops and rough missions. | ⚒️ Moderate – Prone to dents, costly repairs; requires specially trained personnel and high-cost equipment, increasing downtime and expenses. | 💥 Low – Cracks or breaks on impact, requiring costly repairs, extended downtime. |

| Maintenance | ✅ Very Low – No rust, no paint chipping, zero $ cost, NO downtime and NO expenses. | ⚙️ Medium – Moderate corrosion protection—requires galvanic anodes, adding maintenance costs and complexity in harsh marine environments. | 🔧 High maintenance, Osmosis Blisters, Impact Damages, UV Degradation, High Maintenance Costs, high downtime. |

| Weight & Stability | ✅ Lightweight – naturally buoyant, Lightweight (density 0.95 g/cm³), enhances stability in choppy water and safety. | ⚖️ Medium Density – 2.84 times higher (2.7 g/cm³) than HDPE, naturally sinks, less stable in choppy water. | ⚓ Heavier (density ~2.0 g/cm³), naturally sinks, more stable in rough water but harder to tow/launch. |

| Crew Comfort | ✅ High – Superior thermal, impact and acoustic insulation, minimizing crew stress and maximizing operational effectiveness. | 🔊 Poor – Transfers noise and heat to the crew, Noisy in choppy water, vibrations amplify sound. | 🔇 Moderate comfort – quieter than aluminum but lacks HDPE’s thermal/acoustic insulation; heat transfer can be an issue. |

| Fire Resistance | ✅ Self extinguishing, doesn’t sustain combustion—minimizes fire spread, protecting crews in critical situations. | 🔥 Non combustible but conducts heat rapidly—does not burn, but can deform or fail structurally under intense heat. | 🚨 Combustible, burns readily, releases toxic fumes, increases fire hazards, extremely dangerous for the crew. |

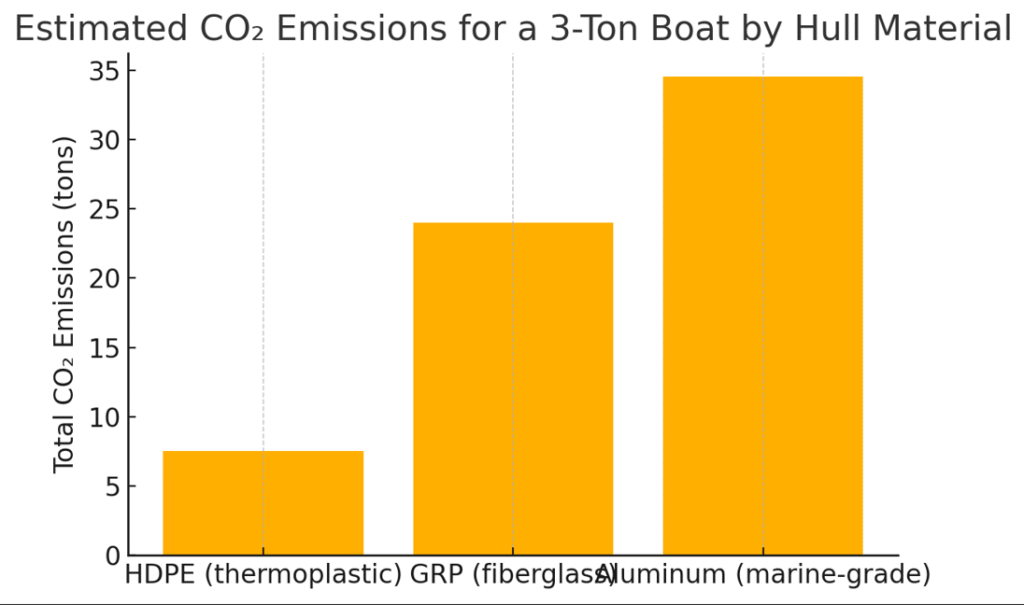

| Environmental Impact | ✅ 100% recyclable – Eco friendly, reduces operational carbon footprint (1.1 tons CO2e for a 3 ton boat), sustainable manufacturing process. | ♻️ Recyclable, but high production footprint (52.4 tons CO2e for a 3 ton boat) due to energy intensive manufacturing (6.8 kWh/lb.). | 🛑 Not recyclable, production emits pollutants, gel coat degrades with UV exposure, increasing carbon footprint. |

| # | Material | CO₂ per ton (t CO₂/t material) |

Boat weight (tons) |

Total CO₂ emissions (tons) |

|---|---|---|---|---|

| 1 | HDPE (thermoplastic) | 2.5 | 3 | 7.5 |

| 2 | GRP (fiberglass) | 8.0 | 3 | 24.0 |

| 3 | Aluminum (marine-grade) | 11.5 | 3 | 34.5 |

Unmatched Support and Services

At DGS Boats, our commitment extends beyond delivering exceptional vessels. We provide comprehensive support, including:

- Exceptional warranty coverage

- Reliable service and maintenance

- Readily available parts

- Direct access to our in-house network of trainers, technicians, and logisticians for ongoing support and training

DGS Boats – Built to Outperform. Do Not Handle With Care.

Ready to experience the DGS difference? Contact us today to learn more about our vessels and how they can meet your mission requirements.

.

certifications

ABYC

American Boat and Yacht Council

DNV – Maritime Classification Excellence

Vessels certified by DNV meet the highest international standards.

US Coast Guard Approved

DVS ZERT GmbH – HDPE

Welding certification of management/ welders – Systems and quality requirements for factory production control.

NMMA - National Marine Manufacturers Association

Type Approved Product

MIASF

Marine Industries Association of South Florida